| 1960 | Foundation |

| 1984 | Established DBS by Mr. Shunzo Yamamoto with 10 million yen capital fund |

| 1996 | The DB-Join Reinforcing Bar Coupler was licensed by The Building Center of Japan (BCJ) |

| 2006 | Receiving GBRC DB Head performance evaluation |

| 2012 | DB-Ring delivery depot opened Shipments of DB-Ring reached 1 million units Branch office in Tokyo opened |

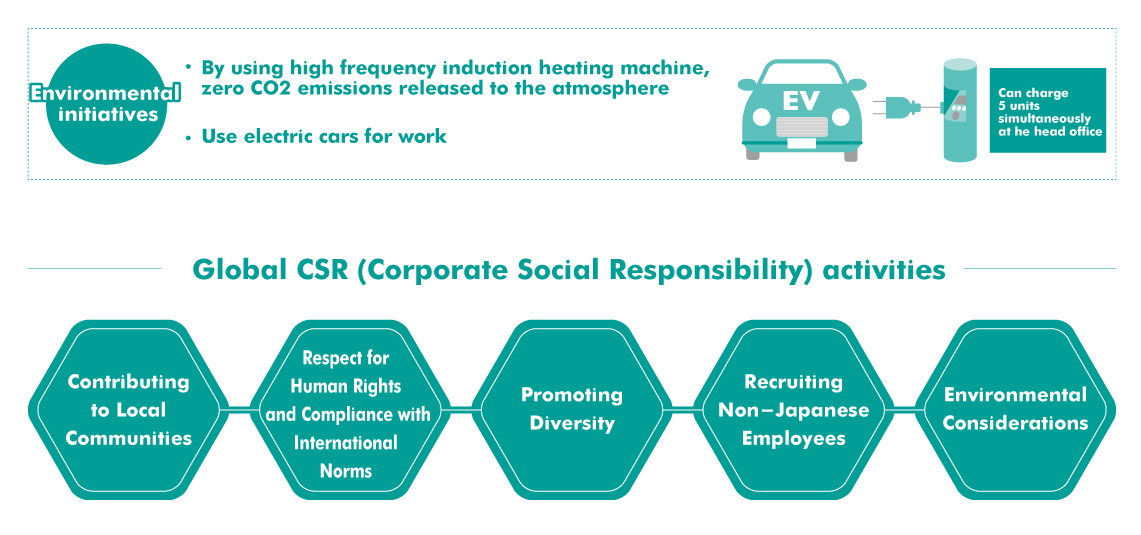

| 2013 | DBS won the Aichi Environmental Excellence Award in 2013 |

| 2014 | The electric vehicle charging infrastructure has been equipped Hamamatsu branch opened |

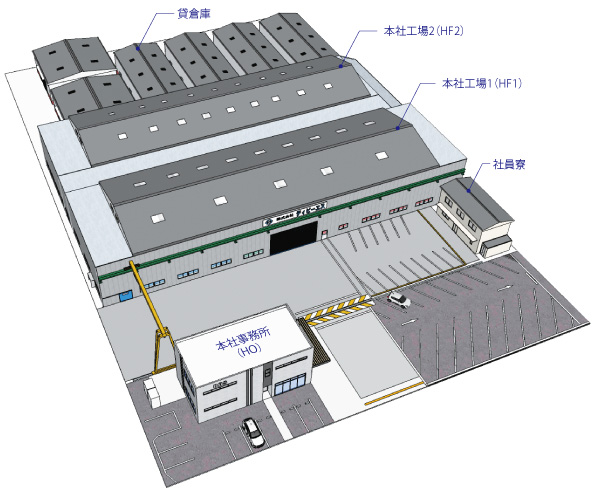

| 2015 | New head office completed |

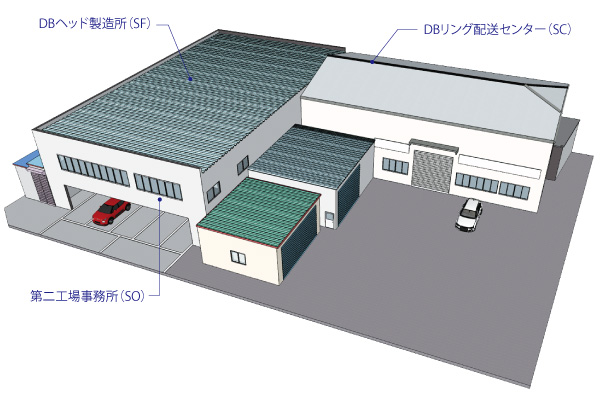

| 2016 | Factory 2 opened Delivery Depot relocated to Delivery Center which is where factory 2 is located |

| 2018 | Toyokawa factory opened |

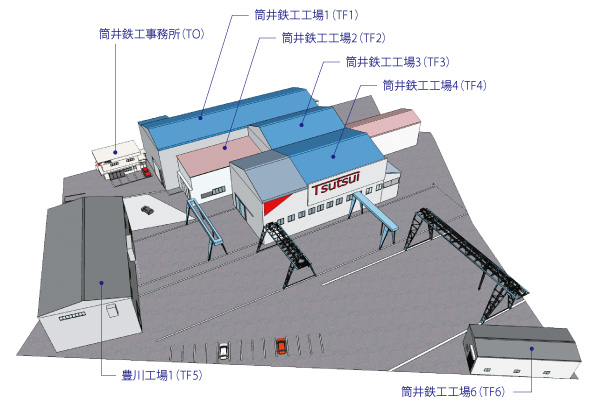

| 2019 | Tsutsui Iron Works became a subsidiary company of DBS |

| Company name | DBS Co.,Ltd |

| Foundation | 31 /3 /1960 |

| Established | 1 / 3 /1984 |

| Main business | Rebar work, DB Head production and sale |

| Licence number | Ministry of Land, Infrastructure, Transport and Tourism (General-27)25991 |

| President&CEO | Shunsuke Yamamoto |

| Capital | 30 million yen |

| Employees | 65 (7 countries) Another employees (70) |

| Head Office | 358-1 Houeicho-Aza-Higashi Toyohashi-City Aichi pref. 441-3125 JAPAN Tel+81-532-41-6316 Facsimile+81-532-41-6425 |

| Tokyo Office | 4F 3-29-19Nishiasakusa Taito-ku Tokyo 111-0035 JAPAN Tel+81-3-6231-6425 Facsimile+81-3-6231-6426 |

| Hamamatsu branch office | 3040-1 Magori-cho Nishi-ku Hamamatsu-City Shizuoka pref. 431-0203 JAPAN Tel&Facsimile+81-53-592-6116 |

| Toyohashi 2nd fact. Product distribution center |

7-9 Higashiwaki 3-chome Toyohashi-City Aichi pref. 441-8083 JAPAN Tel+81-532-39-6682 Facsimile+81-39-6692 |

| Toyokawa | 118 Chigiricho-Suyahara Toyokawa-City Aichi pref JAPAN Tel+81-533-56-7710 Facsimile+81-533-56-7720 |

| Tsutsui Iron Works | 118 Chigiricho-Suyahara Toyokawa-City Aichi pref JAPAN Tel+81-533-83-0111 Facsimile+81-533-83-0444 |

Head Office

Toyohashi 2nd fact.

Toyokawa

Promote from domestic de facto standard to global standard

Inherit the know-how and skills from previous skilled worker

Criteria when using DB Head from manufacture to construction are highly effective

General rebar work (Rebar processing・Rebar assembly)

Since its founding, we have always pursued honesty・accuracy・quickness,taking on the role of the leader in the industry in the development of advanced equipment and techniques of Chuubu region.

Using Pre-assembly method to solve construction time problems and lack of wokers

We want to become a VE (Value Engineering) leader.According to VE proposals, we are actively working on the unit assembly method of construction using DB Head or unit rebar welding machine to shorten the time construction, reduce construction cost, ensure the quality and safety.

Based on advanced technology and knowledge, we propose possible solutions(e.g. new bar processing technology, improve quality, market development , enforcement methods…) for problems and issues facing the industry from a professional viewpoint

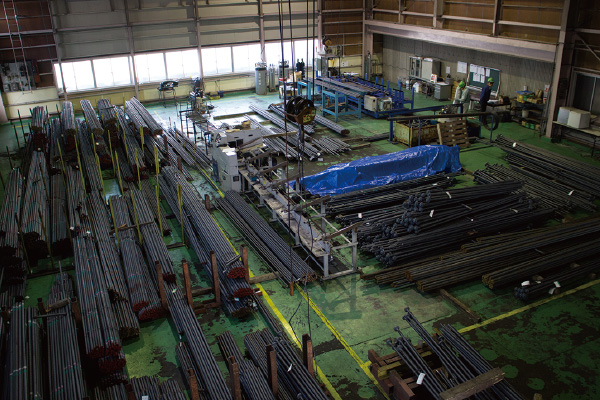

We do consistently rebar processing in the factory

We not only accept normal rebar processing but also special rebar processing

We not only accept normal rebar processing but also special rebar processing

Head office factory

Compact coil

Compact coil Set of products

Set of productsToyohashi factory 2

The world's fastest coil processing machine

The world's fastest coil processing machine  The world's largest rebar NC processing machine

The world's largest rebar NC processing machine

RC segment

RC segment